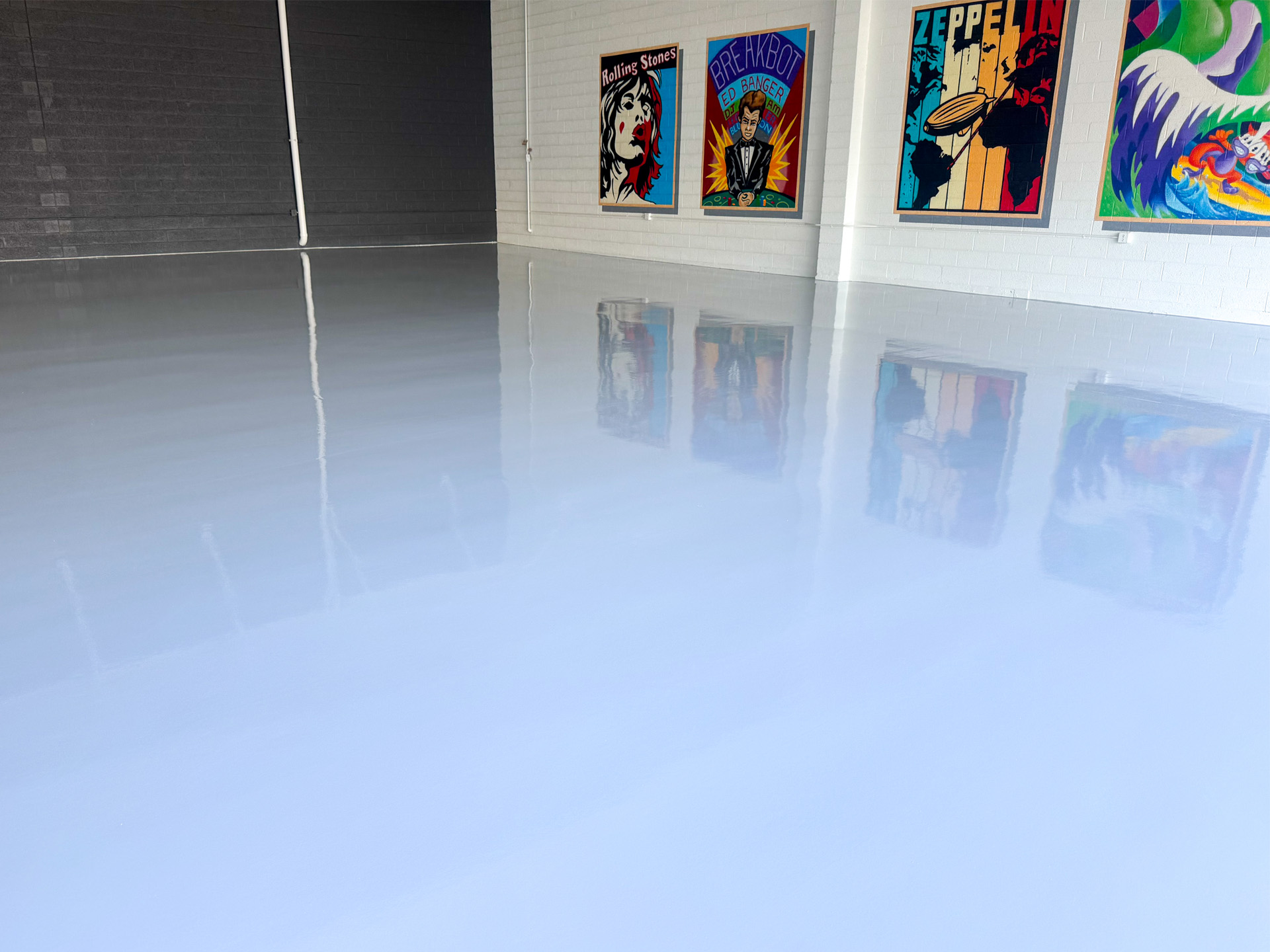

Martori Farms Hangar, Scottsdale AZ — Project of the Week: Resinous Flooring Transformation

A failing hangar floor. Fixed the right way.

When Martori Farms needed to restore the flooring in their Scottsdale, Arizona aircraft hangar, they chose Techniquex for a reason: aviation facilities demand a high-performance surface that can handle jet fuel, hot tires, UV exposure, and constant traffic—without sacrificing appearance. The existing floor was failing and aesthetically displeasing. Our technicians delivered a clean, bright, and incredibly durable finish that will perform for years.

Location: Scottsdale, Arizona

Facility Type: Aviation hangar

Client: Martori Farms

Area Restored: 2,250 sq. ft.

System Installed: DiamondThin Gloss (unlimited moisture control + joint treatment + aliphatic polyester urethane topcoat)

Primary Goals: Restore bond and aesthetics, protect concrete, improve chemical/UV/abrasion resistance, minimize downtime and dust

Why hangar floors fail?

Hangar slabs live a hard life: aircraft wheel loads, fuel and hydraulic fluids, UV from open doors, temperature swings, and abrasive maintenance activities. Many failures trace back to poor surface prep and moisture issues trapped beneath coatings. Our solution starts where lasting results are won or lost—substrate preparation—followed by a moisture-tolerant, chemically robust coating system that won’t yellow or chalk in sunlight.

Our installation process (step-by-step)

1) Controlled removal that protects the slab

To avoid unnecessary substrate damage that can telegraph through finished floors, we mechanically removed the failing coating system using:

Hydraulic riding scrapers to lift bulk material efficiently.

Diamatic planetary grinders to refine the surface and level micro-variations without gouging.

This “gentle but thorough” removal approach preserves concrete integrity and reduces the patchwork repairs that show through glossy finishes.

2) Dust-free, profile-correct surface prep

After removal, we shotblasted the floor to produce a clean, uniform, and mechanically keyed surface. Shotblasting:

Removes embedded contaminants and laitance.

Creates the proper concrete surface profile (CSP) for strong coating adhesion.

Keeps dust controlled for a cleaner, safer jobsite.

3) Unlimited moisture control + joint treatment

With the concrete open and clean, we addressed two chronic failure points:

Moisture control: DiamondThin systems incorporate unlimited moisture tolerance, stopping vapor-related debonding before it starts.

Joint treatment: Properly treating control and construction joints prevents reflective cracking and moisture pumping through weak points.

4) DiamondThin Gloss installation

We installed DiamondThin Gloss, a thin-build, high-gloss resinous system engineered for performance and appearance:

Primer/Body: Bonds deeply with the prepared concrete and levels minor surface variations.

Topcoat – Aliphatic Polyester Urethane: The star of the system, delivering outstanding abrasion, UV, and chemical resistance—ideal for hangar conditions, where tires, fluids, and sunlight converge.

5) Quality checks & finish

Technicians performed adhesion checks, visual inspections, and a final clean to hand off a bright, uniform, and easy-to-maintain surface.

Why DiamondThin Gloss for aviation environments?

If you manage hangar or aerospace facilities, you need a coating system that’s as tough as aircraft operations:

Unlimited moisture control: Mitigates MVT-related failures that plague many hangar floors.

UV stability: Aliphatic urethane resists yellowing and chalking—critical with big doors and bright Arizona sun.

Chemical resistance: Withstands common aviation fluids (fuel, oils, hydraulic fluids, cleaners).

Abrasion resistance: Handles hot-tire pickup, rolling loads, and tool traffic.

Joint treatment built in: Helps control reflective cracking and keeps aesthetics tight.

Low maintenance: Smooth, high-gloss finish that’s simple to clean and keeps a professional appearance.

Results you can see

Crisp, high-gloss finish that elevates the hangar’s visual standard.

Bond-secure system rooted in proper mechanical prep and moisture-tolerant chemistry.

Safer, cleaner workspace with reduced dust and better light reflectivity.

Long-term value thanks to resistance against UV, abrasion, and chemicals—key failure drivers in aviation settings.

Thank you, Martori Farms!

We’re grateful for the trust Martori Farms placed in Techniquex. Partnerships like this push us to continually raise the bar for resinous flooring in Scottsdale, Phoenix Metro, and across the Southwest.

“Special thank you to Martori Farms for choosing Techniquex.”

Considering a hangar or industrial floor upgrade?

If your hangar floor is peeling, yellowing, or stained—or you’re planning a new facility—let’s talk through a no-nonsense plan that starts with surface prep and ends with a finish built for real-world abuse.

System Used: DiamondThin Gloss

Contact us at 877-376-9935 and let’s talk about how we can help transform next project!

Projects of the Week

Don’t Settle for Inferior Foundations

Get a complimentary consultation from the most trusted resinous flooring contractor.